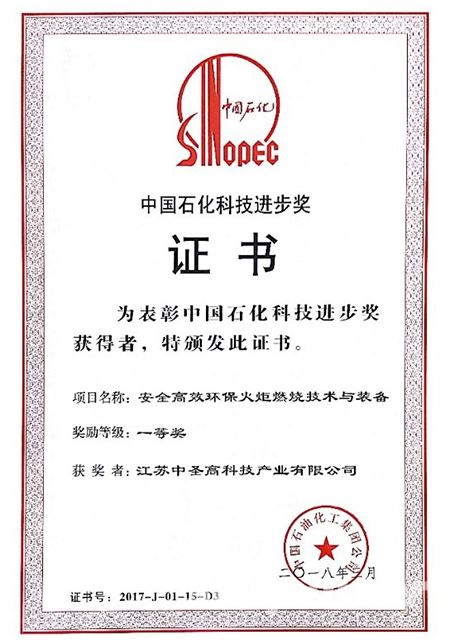

Congratulations on winning the first prize of Sinopec Science and Technology Progress Award by our “safe, efficient and environmentally friendly flare combustion technology and equipment” project.

Recently, our “safe, efficient and environmentally friendly flare combustion technology and equipment” project won the first prize of 2017 Sinopec Science and Technology Progress Award. The project was jointly undertaken by SINOPEC Qingdao Research Institute of Safety Engineering, Sinopec Qilu Branch and Jiangsu Sunpower Technology Co., Ltd.

Considering the situation of lack of effective flare gas burn-up rate testing technology in the domestic flare industry, low ignition success rate and low flare gas burnup rate of the flare system, Sunpower Research Institute and SINOPEC Qingdao Research Institute of Safety Engineering have cooperated in many projects and have many new breakthroughs and achievements in the field of flare: a super-large flare burn-up rate test platform has been established to test the flare combustion parameters (burn-up rate, flame temperature and shape, heat radiation and combustion noise); the combustion mechanism model VSOOT for intermediate products of flare combustion process and soot has been developed, and tested and verified in industrial level flare combustion equipment, and applied to large-scale ground flare combustion field design, flare burner development, low calorific value gas and acid gas combustion optimization design; an integrated energy-saving pilot and flare ignition system has been developed which is featured by strong weather resistance, low air consumption (1.5-2.0 Nm3/h), reliable and stable ignition.

The research results have been applied in Qilu Petrochemical, Luoyang Petrochemical, BASF Singapore, Shell Iraq and other projects. The use shows that pilot ignition is efficient and stable and consumes less gas, and the flare has high burn-up rate and no black smoke. On-line flame monitoring is possible. It is safe and reliable, and practices the concept of “profitable environmental protection” of Sunpower.