The professional design team is completely equipped with professional design software, and is available with Grade A certification in chemical, petrochemical and medicine industries;

H2S cracking (the 2nd generation sulfur recovery technology) pilot plant of Sunpower Group - hydrogen sulfide cracking-to-sulfur process

A innovative sulfur recovery unit

A innovative sulfur recovery unit that is based on new reaction mechanism and new cracking catalyst and that is characterized by less investment, small floor space, simple flow path, low operation cost and the like, compared to traditional process; currently, this technology has completed pilot test and has entered the industrialized application stage. Traditional sulfur recovery process is efficiently integrated with new technologies and new products, thus forming a fire-new hydrogen sulfide cracking-to-sulfur process. The future sulfur recovery unit is assigned with economic benefit point, thus allowing it to become an oil-refining chemical unit combined with economic benefit, environmental benefit and social benefit.

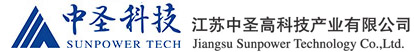

KT S.O.A.P.™ VS BENCHMARK SRU PROCESS

H2S Cracking Section with KT PROPRIETARY CATALYST

NO SO2 production (ppm)NO Claus Reactors

H2 Rich Gas production

NO Incinerator

KT S.O.A.P.™ - PROCESS FLOW SCHEME

Main features

Use of S.O.A.P.™ Catalyst - KT Proprietary Catalyst

Fully integrated in KT BAT RAR™ TGT

Use of new DOW UCARSOL™ Amine Solvent specifically developed for KT Novel Process

-

4×200ktpa chlorine hydride energy-saving technical revampment project of Golden Concord Holdings Limited4×200ktpa chlorine hydride energy-saving technical revampment project of Golden Concord Holdings Limited+

4×200ktpa chlorine hydride energy-saving technical revampment project of Golden Concord Holdings Limited4×200ktpa chlorine hydride energy-saving technical revampment project of Golden Concord Holdings Limited+ -

The dry mixing revampment project of stage II of Phase I of Sinkiang Xiexin Polysilicon CompanyThe dry mixing revampment project of stage II of Phase I of Sinkiang Xiexin Polysilicon Company+

The dry mixing revampment project of stage II of Phase I of Sinkiang Xiexin Polysilicon CompanyThe dry mixing revampment project of stage II of Phase I of Sinkiang Xiexin Polysilicon Company+ -

The optimization operation revampment project for the granular silicon, carbon white and semiconductor of Xinhua CompanyThe optimization operation revampment project for the granular silicon, carbon white and semiconductor of Xinhua Company+

The optimization operation revampment project for the granular silicon, carbon white and semiconductor of Xinhua CompanyThe optimization operation revampment project for the granular silicon, carbon white and semiconductor of Xinhua Company+ -

The 36t/h biomass boiler project of Unipower New Energy of Environmental Protection Inc.The 36t/h biomass boiler project of Unipower New Energy of Environmental Protection Inc.+

The 36t/h biomass boiler project of Unipower New Energy of Environmental Protection Inc.The 36t/h biomass boiler project of Unipower New Energy of Environmental Protection Inc.+ -

The formaldehyde-to-rubber and plant-wide auxiliary project of Jiangsu Jinhui Chemical Co., LtdThe formaldehyde-to-rubber and plant-wide auxiliary project of Jiangsu Jinhui Chemical Co., Ltd+

The formaldehyde-to-rubber and plant-wide auxiliary project of Jiangsu Jinhui Chemical Co., LtdThe formaldehyde-to-rubber and plant-wide auxiliary project of Jiangsu Jinhui Chemical Co., Ltd+

The main personnel of various design departments, who come from large-sized engineering design organizations or the state-owned design institutes directly affiliated to large-sized refineries, deal with the flow path planning of oil-refining enterprises, the design of unit and flow path, the expansion and potential-tapping revampment of unit and the like for a long time, thus being available with quite rich engineering experience.

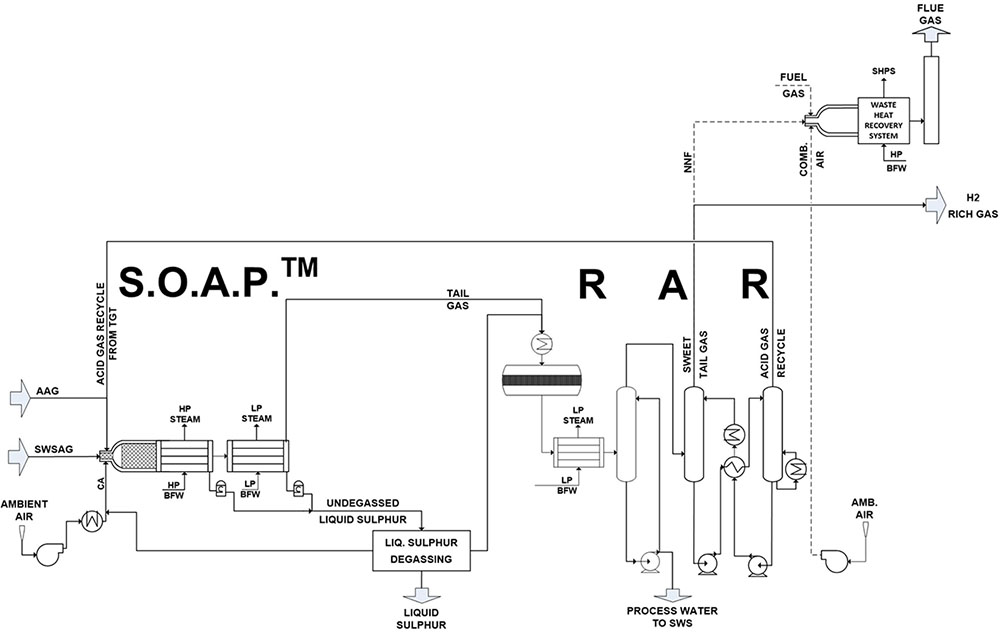

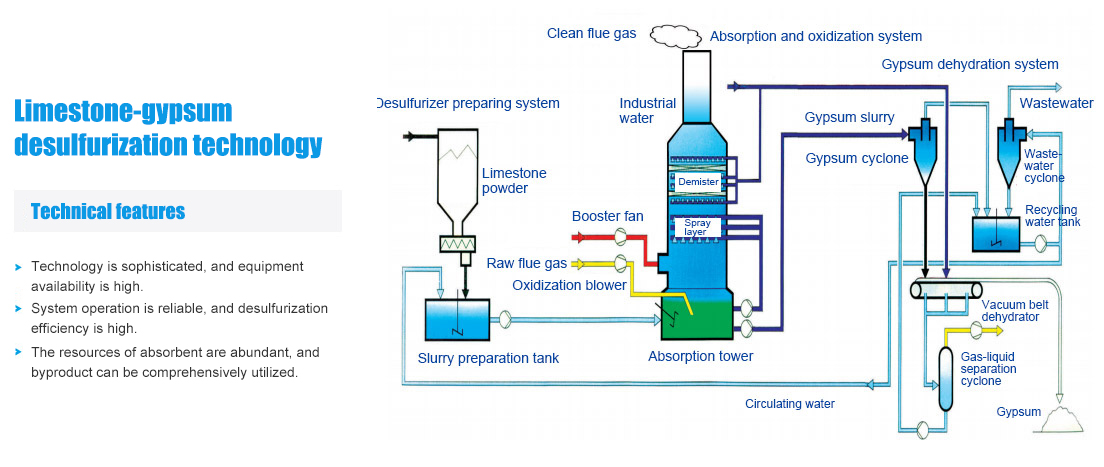

Applications

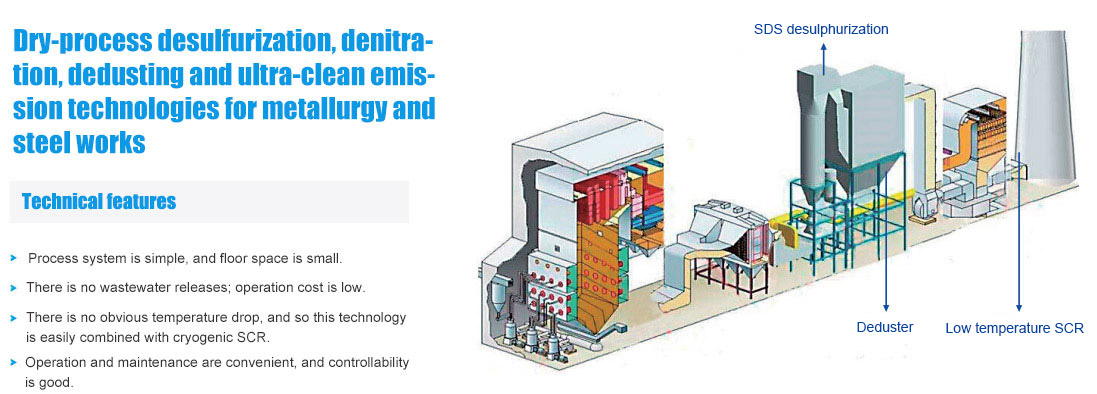

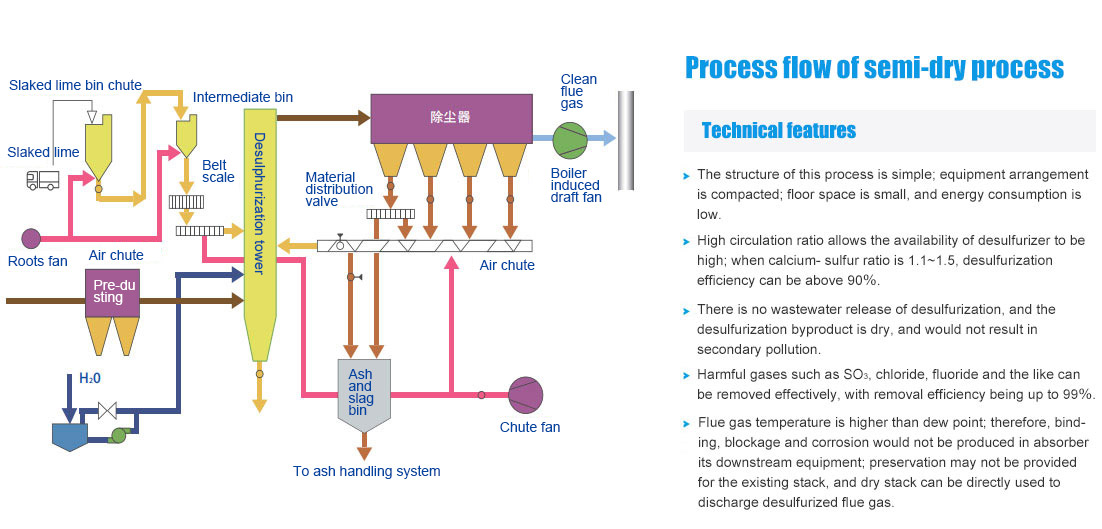

The technologies are applied in boiler, refinery, metallurgy, industrial kiln, coking industry and the like to treat the pollutants produced such as sulfur dioxide, nitrogen oxide, dust and so on, thus meeting applicable national standards.

Technical advantages

This Company has many application achievements regarding the projects of self-contained power generation equipment below 300MW, and can provide you with strong guarantee in the aspect of optimization design, routine maintenance, operation, the resolution of troublesome failure and the like.

This Company possesses the manufacturing base and manufacturing capacity of large-sized equipment, as well as multiple technical patents and residual heat recovery technology.

This Company possesses the high-efficiency research & development team of technology and abundant startup experience of units.

The collocation of a great variety of FGD & CR process provides you with the proprietary process suitable to the enterprise according to actual situation, so as to reduce investment and operation cost.

Dry-process desulfurization technology

Reactive code desulfurization technology

Semi-dry-process desulfurization technology

Composite amine desulfurization technology

SNCR technology

CR technology

-

Yunnan Dawei Coke-producing Co., Ltd - 2×1000ktpa coke oven FGD & SCR projectYunnan Dawei Coke-producing Co., Ltd - 2×1000ktpa coke oven FGD & SCR project+

Yunnan Dawei Coke-producing Co., Ltd - 2×1000ktpa coke oven FGD & SCR projectYunnan Dawei Coke-producing Co., Ltd - 2×1000ktpa coke oven FGD & SCR project+ -

Yangmei Taiyuan Chemical New Material Co., Ltd - 4×280t/h boiler FGD ultra-low revampment projectYangmei Taiyuan Chemical New Material Co., Ltd - 4×280t/h boiler FGD ultra-low revampment project+

Yangmei Taiyuan Chemical New Material Co., Ltd - 4×280t/h boiler FGD ultra-low revampment projectYangmei Taiyuan Chemical New Material Co., Ltd - 4×280t/h boiler FGD ultra-low revampment project+ -

Coke oven FGD, SCR and dedusting project of Shanxi Taigang Stainless Steel Co., LtdCoke oven FGD, SCR and dedusting project of Shanxi Taigang Stainless Steel Co., Ltd+

Coke oven FGD, SCR and dedusting project of Shanxi Taigang Stainless Steel Co., LtdCoke oven FGD, SCR and dedusting project of Shanxi Taigang Stainless Steel Co., Ltd+ -

Qinghai Damei - 3×240t/h boiler wet-process FGD unitQinghai Damei - 3×240t/h boiler wet-process FGD unit+

Qinghai Damei - 3×240t/h boiler wet-process FGD unitQinghai Damei - 3×240t/h boiler wet-process FGD unit+ -

The environmental protection engineering of the relocation project of Xintai Zhengda Thermoelectric Co. Ltd - 3×130t/h desulfurization worksThe environmental protection engineering of the relocation project of Xintai Zhengda Thermoelectric Co. Ltd - 3×130t/h desulfurization works+

The environmental protection engineering of the relocation project of Xintai Zhengda Thermoelectric Co. Ltd - 3×130t/h desulfurization worksThe environmental protection engineering of the relocation project of Xintai Zhengda Thermoelectric Co. Ltd - 3×130t/h desulfurization works+ -

Desulfurization engineering of the cogeneration project of Shantou Caonan Comprehensive Weaving Printing and Dyeing Environmental Protection Treatment CenterDesulfurization engineering of the cogeneration project of Shantou Caonan Comprehensive Weaving Printing and Dyeing Environmental Protection Treatment Center+

Desulfurization engineering of the cogeneration project of Shantou Caonan Comprehensive Weaving Printing and Dyeing Environmental Protection Treatment CenterDesulfurization engineering of the cogeneration project of Shantou Caonan Comprehensive Weaving Printing and Dyeing Environmental Protection Treatment Center+ -

The flue gas emission technical revampment project of Quanjiao Sunpower Clean Energy Co., LtdThe flue gas emission technical revampment project of Quanjiao Sunpower Clean Energy Co., Ltd+

The flue gas emission technical revampment project of Quanjiao Sunpower Clean Energy Co., LtdThe flue gas emission technical revampment project of Quanjiao Sunpower Clean Energy Co., Ltd+ -

The FGD unit of the thermal power project of Hebei Changrun Environmental Protection Science and Technology Co., LtdThe FGD unit of the thermal power project of Hebei Changrun Environmental Protection Science and Technology Co., Ltd+

The FGD unit of the thermal power project of Hebei Changrun Environmental Protection Science and Technology Co., LtdThe FGD unit of the thermal power project of Hebei Changrun Environmental Protection Science and Technology Co., Ltd+

No data!