Year 1997, Sunpower Established.

Year 1997, flare Expert introduction.

Year 2000, to supply components of flare system (Flare tip, Seal-water drum, Knot out drum).

Year 2002, Jinan Iron Company Flare relocated and flare gas recovery system (First EP Elevated flare system contract (Guyed)).

Year 2003, Shanghai Secco Petrochemical Company AN flare project (First EP Elevated Flare System (Derrick))

Year 2003, Zhejiang Yisheng Petrochemical Company Methane flare and recovery project. (First EP Enclosed Ground flare and recovery system contract)

Year 2005, Shenhua Coal to Liquids Company Erdos project (First EPC Elevated flare and recovery system contract)

Year 2008, CNPC international Turkmenistan Stage one Natural Gas project (First oversea flare project)

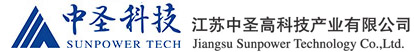

Year 2008, Shenhua Baotou Coal to Olefin project (First Self-supported flare system EPC project)

Year 2012, CNPC Sichuan Petrochemical project (First demountable elevated Flare)

Year 2014, Fund (Changzhou) Energy and Chemical Company MTO, MS project (First Multi-point Open Ground Flare EPC project)

Year 2015, became SHELL EFA Flare supplier.

-

Shenhua Coal to Liquids Company Erdos project (First EPC Elevated flare and recovery system contract)Shenhua Coal to Liquids Company Erdos project (First EPC Elevated flare and recovery system contract)+

Shenhua Coal to Liquids Company Erdos project (First EPC Elevated flare and recovery system contract)Shenhua Coal to Liquids Company Erdos project (First EPC Elevated flare and recovery system contract)+ -

Shenhua Baotou Coal to Olefin projectShenhua Baotou Coal to Olefin project+

Shenhua Baotou Coal to Olefin projectShenhua Baotou Coal to Olefin project+ -

CNPC Sichuan Petrochemical projectCNPC Sichuan Petrochemical project+

CNPC Sichuan Petrochemical projectCNPC Sichuan Petrochemical project+ -

China coal shaanxi yulin energy & chemical co. LTDChina coal shaanxi yulin energy & chemical co. LTD+

China coal shaanxi yulin energy & chemical co. LTDChina coal shaanxi yulin energy & chemical co. LTD+ -

Changzhou fude energy & chemical coChangzhou fude energy & chemical co+

Changzhou fude energy & chemical coChangzhou fude energy & chemical co+ -

Zhongtian hechuang energy co. LTDZhongtian hechuang energy co. LTD+

Zhongtian hechuang energy co. LTDZhongtian hechuang energy co. LTD+ -

Shenhua ning coal 4 million tons/year coal indirect liquefaction projectShenhua ning coal 4 million tons/year coal indirect liquefaction project+

Shenhua ning coal 4 million tons/year coal indirect liquefaction projectShenhua ning coal 4 million tons/year coal indirect liquefaction project+ -

Shasoyihai alcohol industry co., LTD. 60,000 tons/year fatty alcohol projectShasoyihai alcohol industry co., LTD. 60,000 tons/year fatty alcohol project+

Shasoyihai alcohol industry co., LTD. 60,000 tons/year fatty alcohol projectShasoyihai alcohol industry co., LTD. 60,000 tons/year fatty alcohol project+ -

China national petroleum international corporation soil storage phase 1 and phase 2 natural gas projectsChina national petroleum international corporation soil storage phase 1 and phase 2 natural gas projects+

China national petroleum international corporation soil storage phase 1 and phase 2 natural gas projectsChina national petroleum international corporation soil storage phase 1 and phase 2 natural gas projects+ -

180,000 tons/year isonanol plant project of maoming petrochemical basf co., LTD180,000 tons/year isonanol plant project of maoming petrochemical basf co., LTD+

180,000 tons/year isonanol plant project of maoming petrochemical basf co., LTD180,000 tons/year isonanol plant project of maoming petrochemical basf co., LTD+ -

SAMAC MMA-PMMASAMAC MMA-PMMA+

SAMAC MMA-PMMASAMAC MMA-PMMA+ -

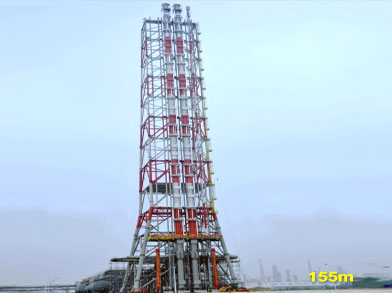

Yangzi petrochemical flare gas and recovery systemYangzi petrochemical flare gas and recovery system+

Yangzi petrochemical flare gas and recovery systemYangzi petrochemical flare gas and recovery system+ -

Cnooc huizhou refinery project torch gas recovery facilitiesCnooc huizhou refinery project torch gas recovery facilities+

Cnooc huizhou refinery project torch gas recovery facilitiesCnooc huizhou refinery project torch gas recovery facilities+ -

Qinghai salt lake haina chemical co. LTDQinghai salt lake haina chemical co. LTD+

Qinghai salt lake haina chemical co. LTDQinghai salt lake haina chemical co. LTD+ -

Qinghai salt lake haina chemical co. LTDQinghai salt lake haina chemical co. LTD+

Qinghai salt lake haina chemical co. LTDQinghai salt lake haina chemical co. LTD+ -

Petrochina lanzhou petrochemical company refineryPetrochina lanzhou petrochemical company refinery+

Petrochina lanzhou petrochemical company refineryPetrochina lanzhou petrochemical company refinery+ -

Zhejiang petrochemical torch gas recycling project - under constructionZhejiang petrochemical torch gas recycling project - under construction+

Zhejiang petrochemical torch gas recycling project - under constructionZhejiang petrochemical torch gas recycling project - under construction+

Computer center

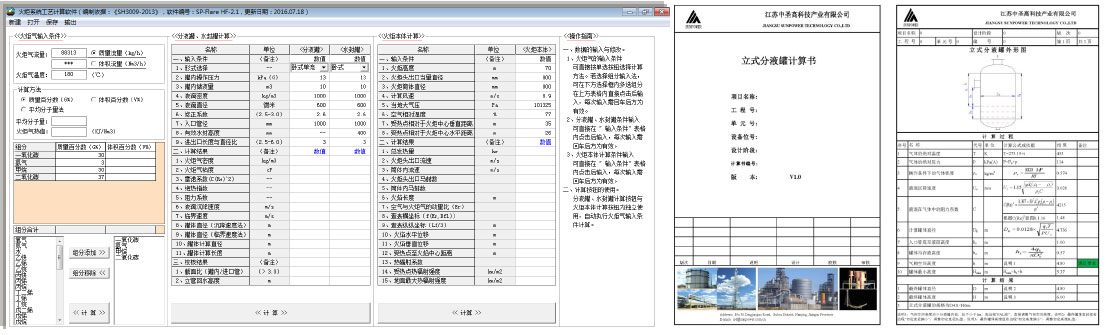

In-house developed process design software

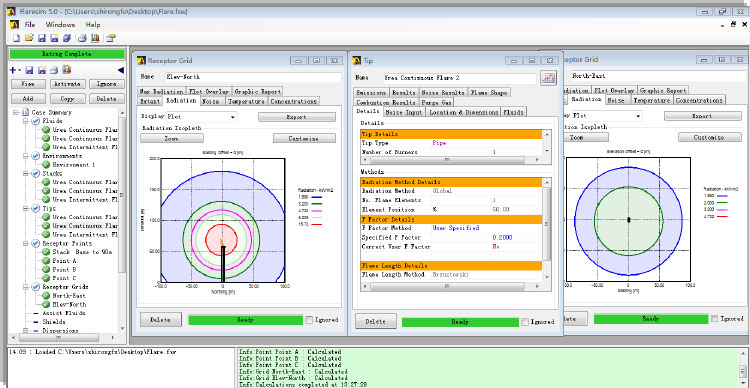

Professional design software: Flaresim, CFD simulation (ability to calculate 10 million node)

Simulation

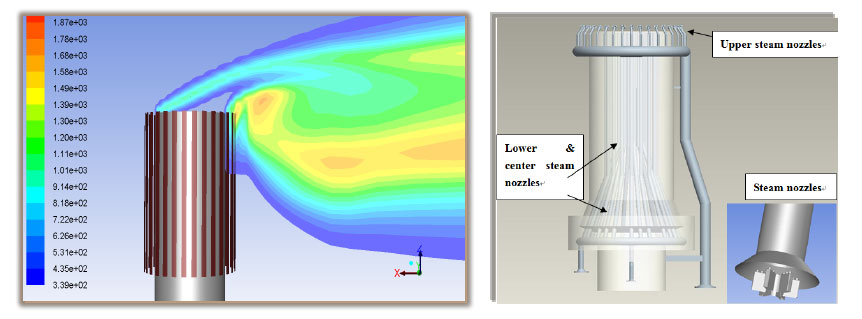

Simulate and optimize for ground flare burner by using CFD.

Simulation for Enclosed Ground Flare. Simulation for Multi-point Ground Flare.

Simulate and optimize for ground flare burner by using CFD.

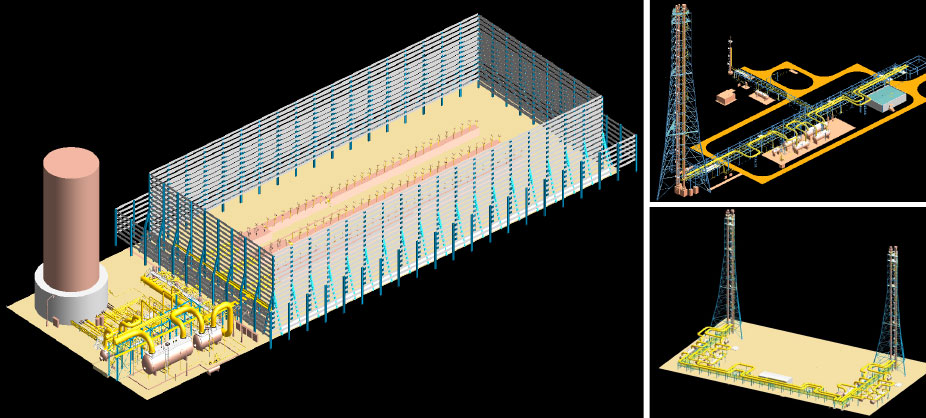

3D design

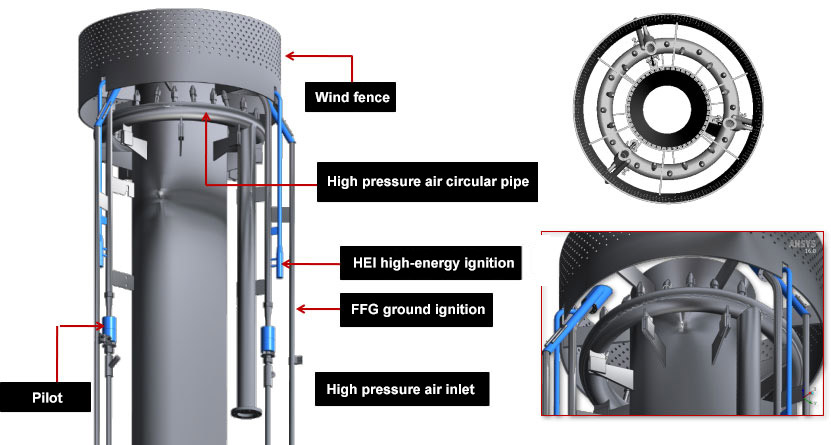

High pressure air smoke extinguisher torch head

Torch facility 3D model

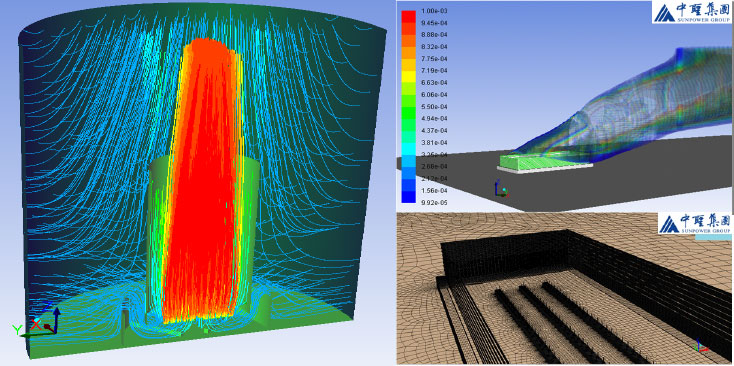

The result is reviewed by the experts from Sinopec Engineering Institute, Power and Energy of Nanjing Normal University, Sinopec safety and engineering institute, Shenhua Coal to Liquid etc., and also SHELL representative from The Netherlands. Confirm the testing methods is acceptable, the testing facility is reliable and calibrated, and the recorded data is trustable.

Combustion test of large surface torch burner before delivery